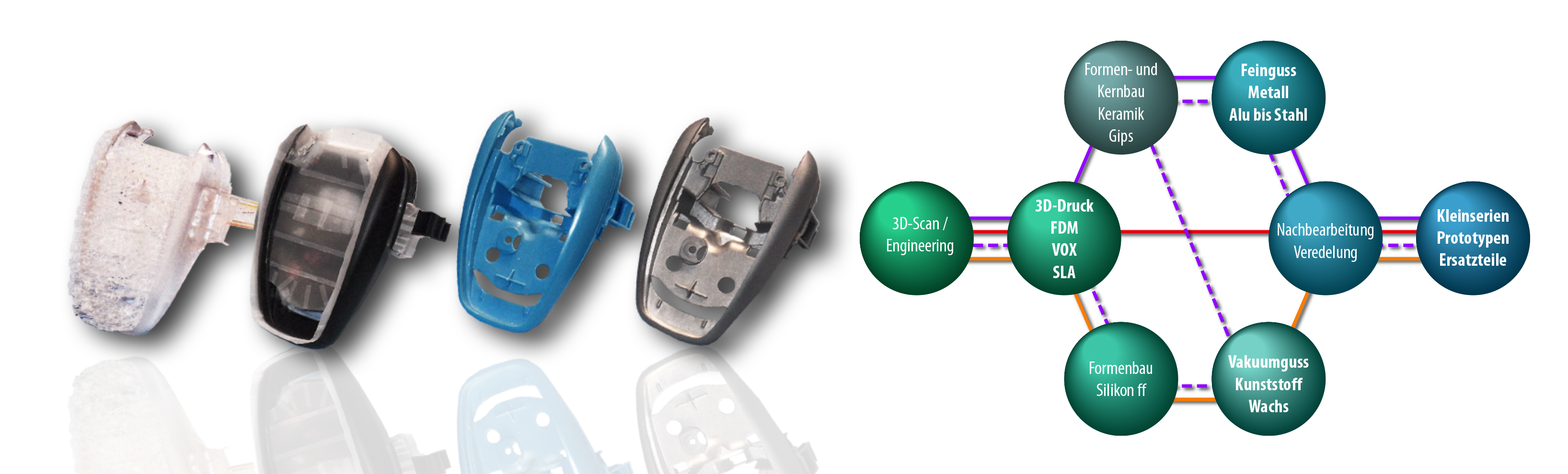

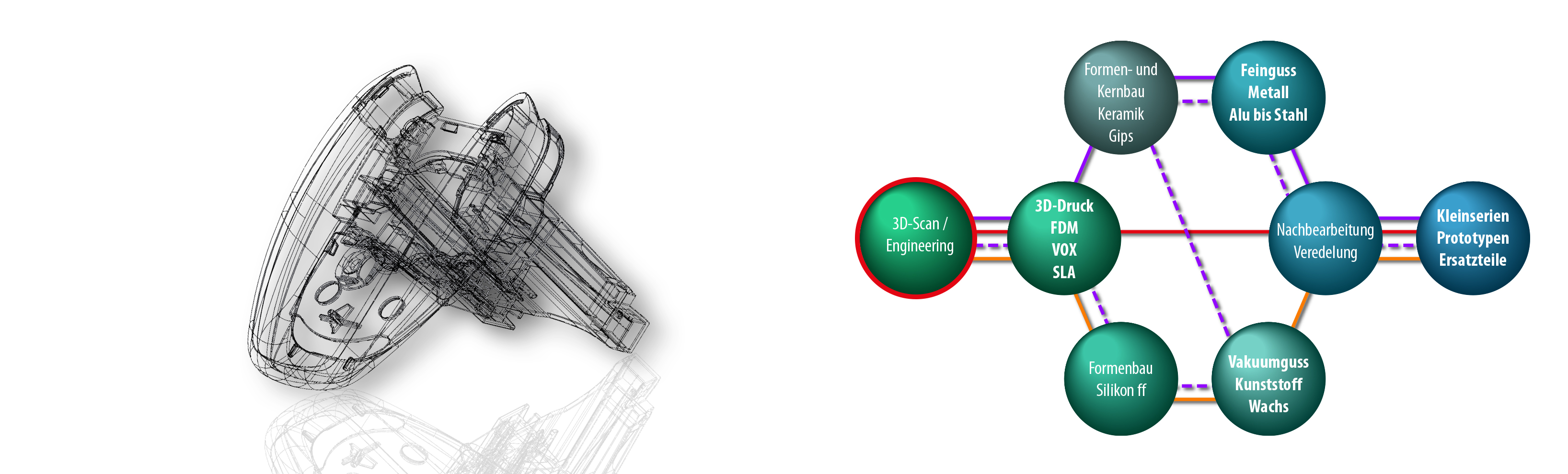

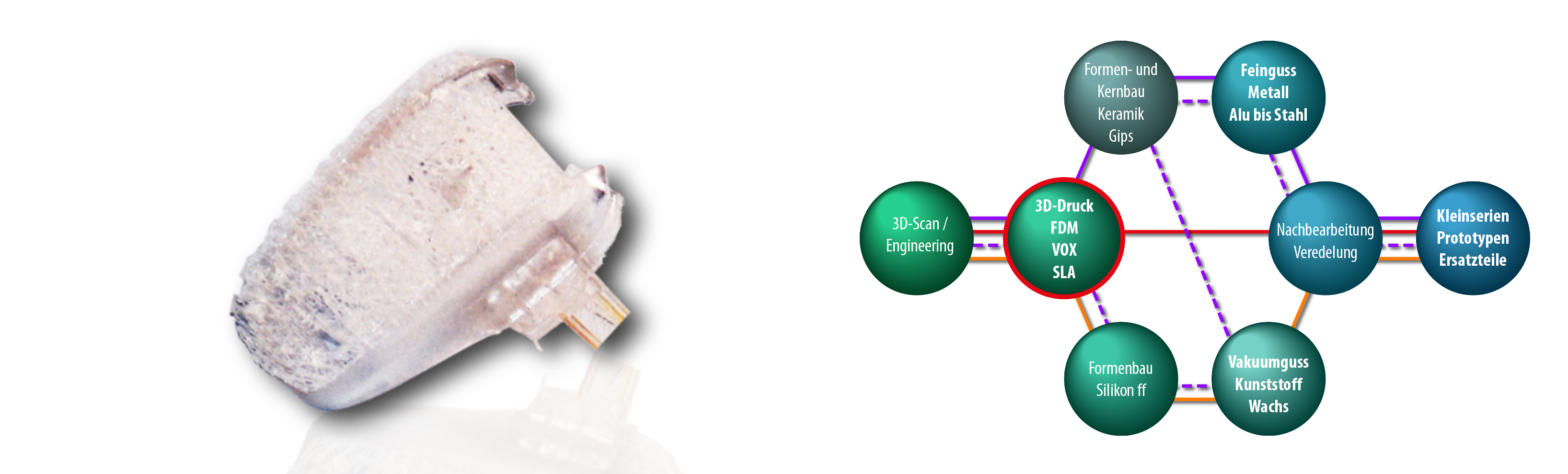

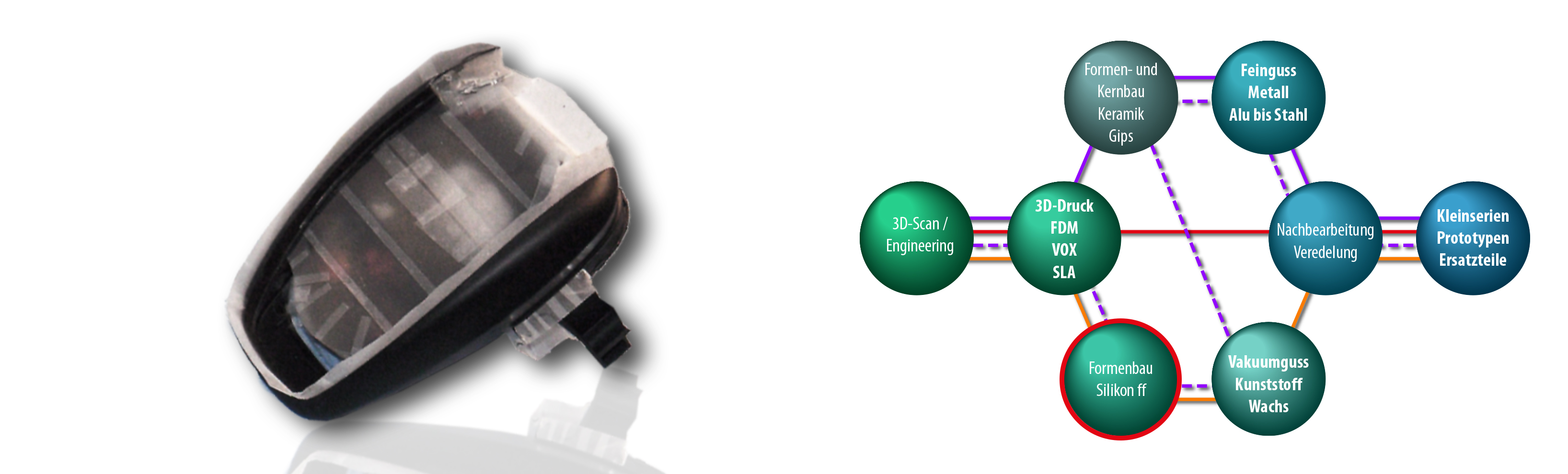

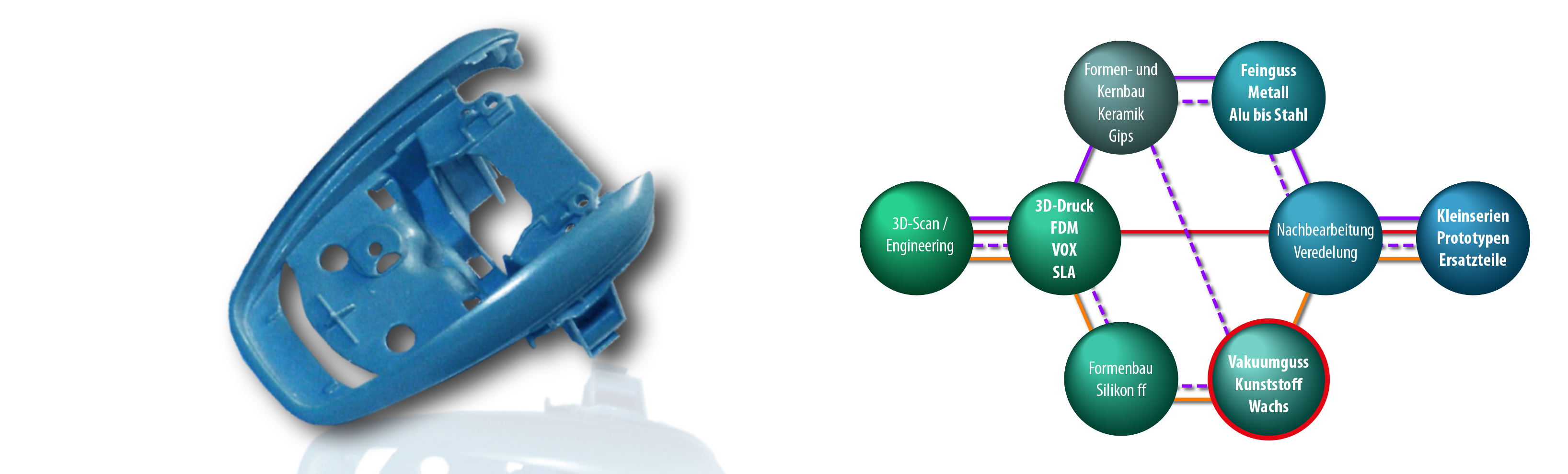

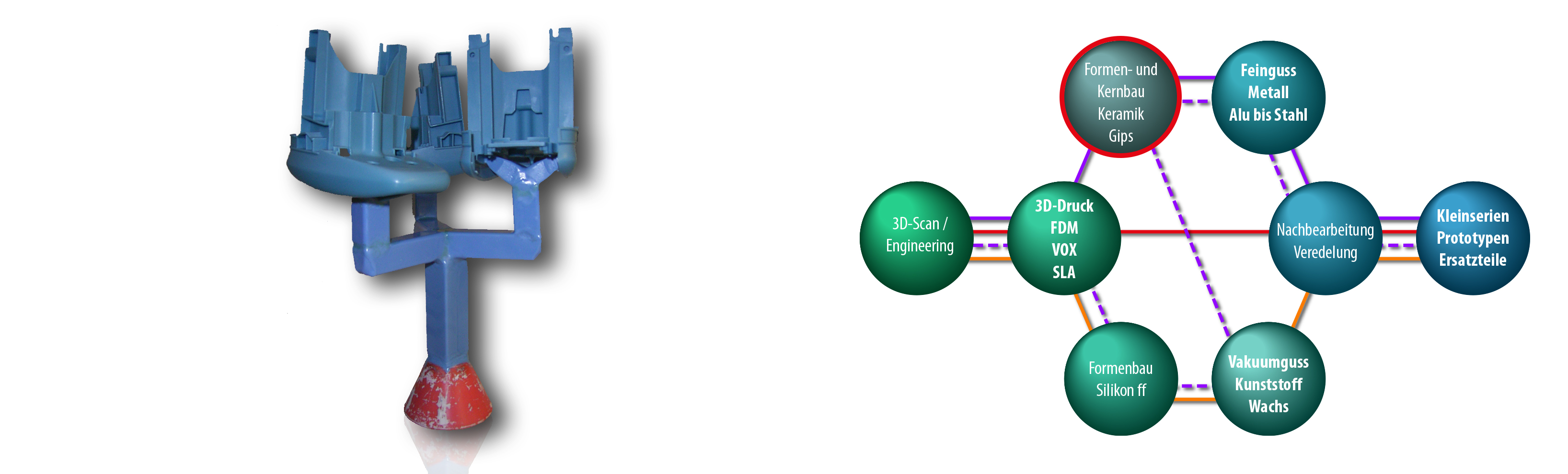

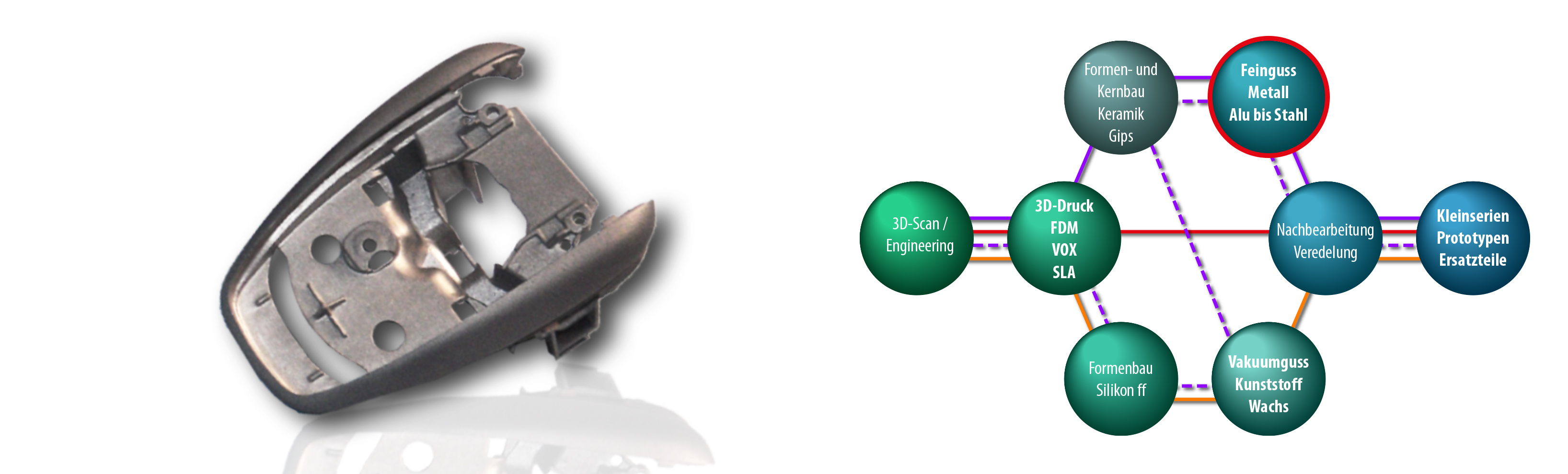

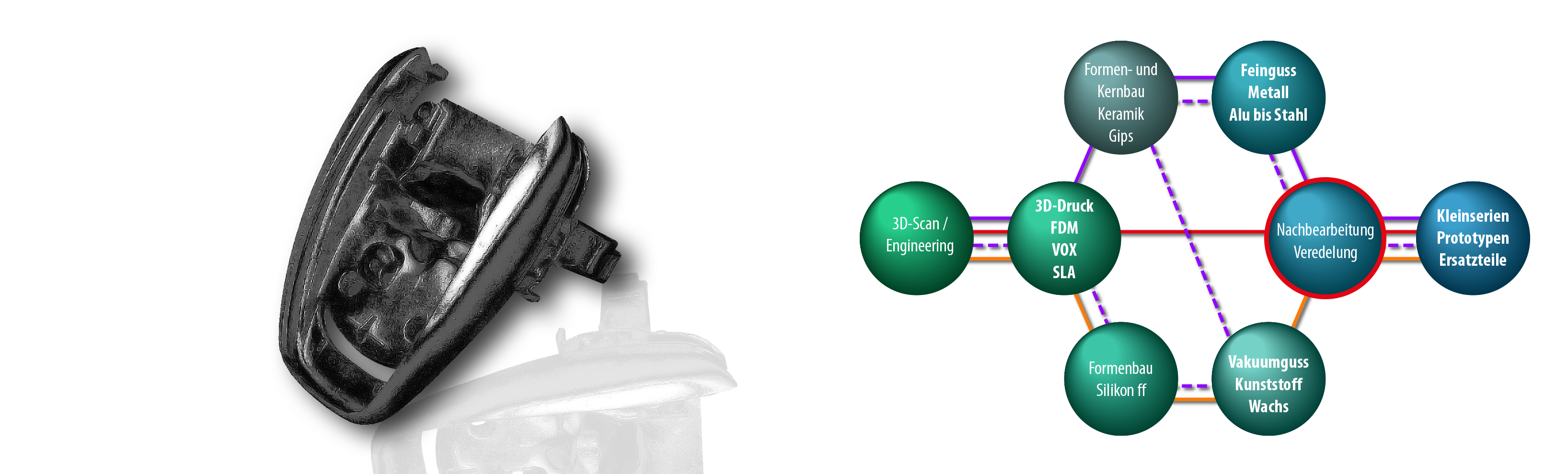

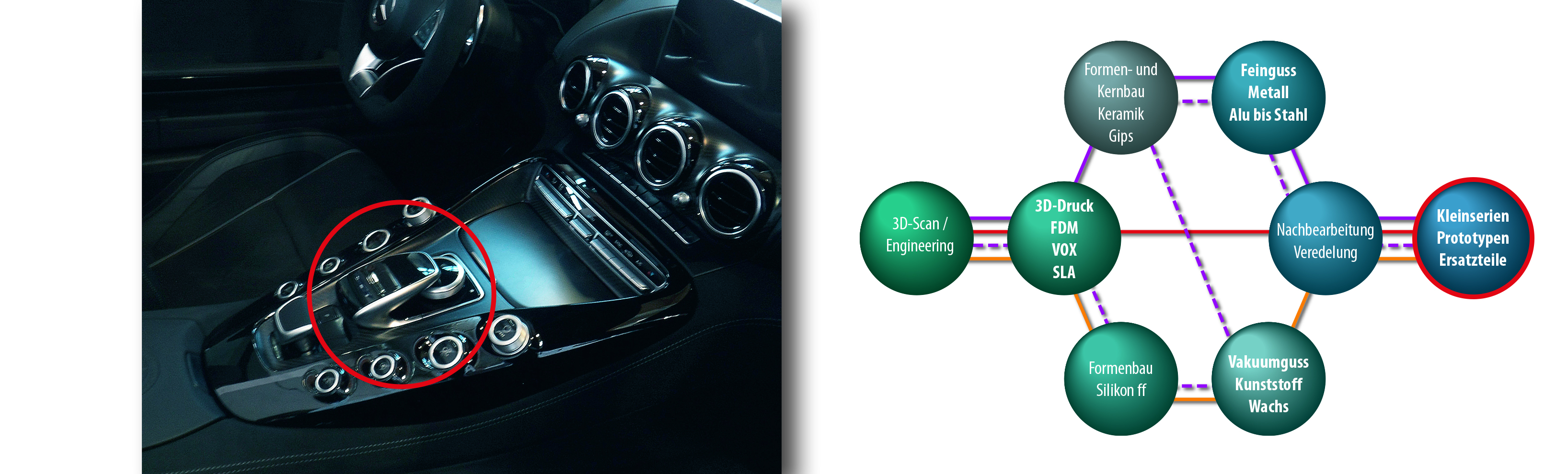

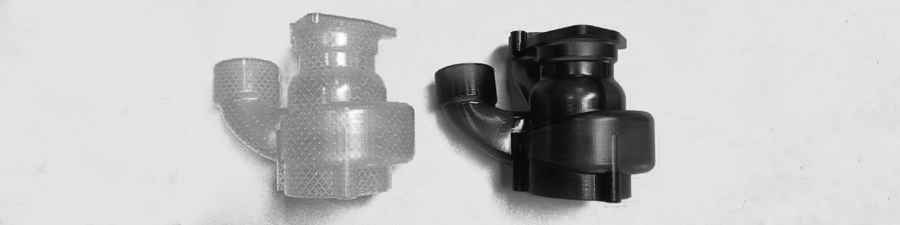

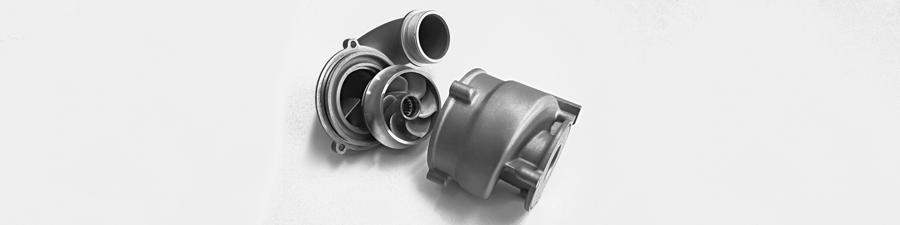

"Für unsere Kunden kombinieren wir 3D-Druck und Gießtechniken für Kunststoff und Metall."

Mit den Technologien unserer Prozesskette im eigenen Hause gewährleisten wir schnelle Lieferzeiten sowie eine kosteneffiziente Abarbeitung. Während des gesamten Auftragsdurchlaufes steht Ihnen ein Ansprechpartner in allen technischen und wirtschaftlichen Belangen zur Seite. Somit können innerhalb der einzelnen Prozessschritte geometrische Detailänderungen ebenso berücksichtigt werden wie Stückzahl-, Losgrößen- oder Lieferterminanpassungen.

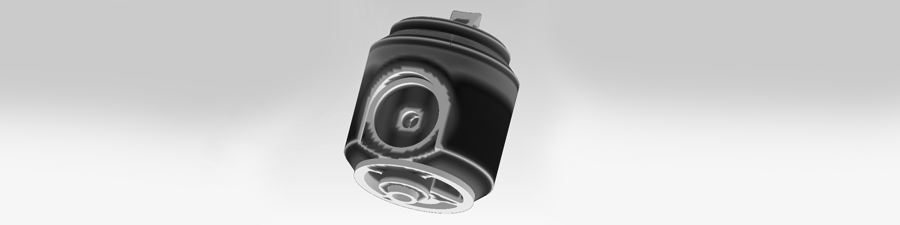

Für die schnelle Herstellung von Prototypen, Gussteilmustern oder Versuchsteilen steht uns eine Vielfalt von generativen Fertigungs- und Feinguss-Technologien zur Verfügung. Jede dieser Technologien, Techniken und Maschinen haben einen Bereich hoher Prozessstabilität aber auch eine weite Bandbreite an Einsatzmöglichkeitne. Mit den Kundenvorgaben an das neue Produkt und den sich ableitenden Anforderungen an die Fertigungsverfahren testen wir die Grenten der Technologien aus und entwickeln unsere Herstellungstechniken weiter.